Initially, raw water is collected from a deep tube well, about 500 feet below the ground level, using a submersible pump and the water is transferred and stored in a fully enclosed raw water tank.

Next, the raw water passes through a series of filtration vessels before entering the membranes of the Reverse Osmosis Unit.

Initially, raw water is collected from a deep tube well, about 500 feet below the ground level, using a submersible pump and the water is transferred and stored in a fully enclosed raw water tank.

Next, the raw water passes through a series of filtration vessels before entering the membranes of the Reverse Osmosis Unit.

To neutralize and remove dissolved chlorine, odor & taste, if any

To remove salts of calcium and magnesium to make water free of hardness and finally conditioned for Reverse Osmosis (RO) system

At this stage, high pressure RO pump pushes filtered soft water to RO pressure vessels, within which RO membranes separate feed water into “permeate water” and “reject water”. Permeate water (RO water) is collected in the RO Water Holding Tank and reject water is discharged into the drain.

To remove salts of calcium and magnesium to make water free of hardness and finally conditioned for Reverse Osmosis (RO) system.

At this stage, high pressure RO pump pushes filtered soft water to RO pressure vessels, within which RO membranes separate feed water into “permeate water” and “reject water”. Permeate water (RO water) is collected in the RO Water Holding Tank and reject water is discharged into the drain.

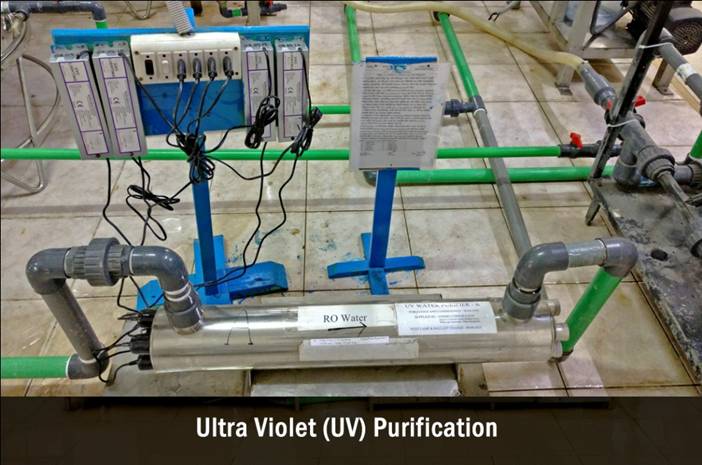

To make drinking water free from pathogenic micro-organisms, it is treated with UV rays through our UV purification systems which is an anti-contamination system where the UV radiation kills and inactivates further growth of micro-organisms.

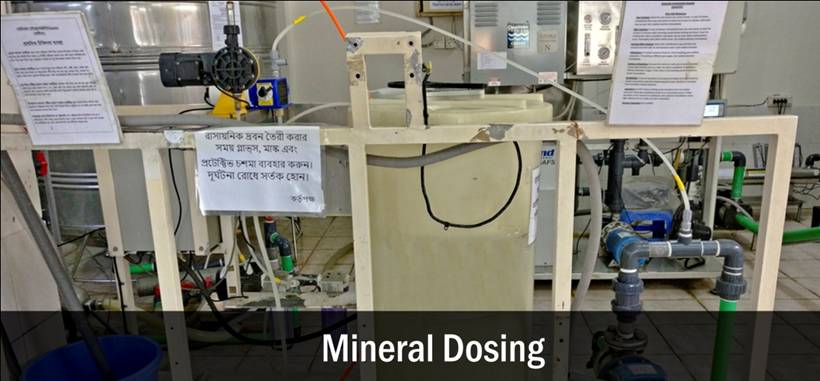

The pH of permeate water usually ranges from 5.5 - 5.8. To enhance the pH of water, Mineral Dosing is performed. The pH of water is strictly maintained between 7.0 and 7.4 and to ensure that, pH value is strictly monitored and recorded in daily log sheet.

The treated water then passes through 20 µm & 5 µm cartridge sediment filters for further removal of any suspended solids or particulates present in water.

The treated water is stored in an Intermediate Tank from where the water passes through another UV Water Purifier and the resulting water then goes through Ozone Treatment.

The water is finally ready to be filled in jars and is stored in the Product Water Storage Tank.

Here at Alpine Fresh Water System Limited, a seven-stage cleaning procedure is strictly followed and maintained in order to clean, wash, sanitize and disinfect the bottles before they go through the final stage of washing, filling and capping, prior to getting delivered to our valuable customers.

Upon receiving the empty returned-bottles at our “Unloading Points” inside our factory premises, the jars undergo a “sniff test” to detect any kind of smell coming from inside, through the mouth of the bottles. If an odour of any kind is detected, the particular bottles are separated and sent away to be destroyed later on. The same goes for bottles found with cracks or breaks.

Then empty bottles are counted and a slip showing number of the jars returned is issued to delivery supervisor of Jar distributor.

The bottles are then arranged and the outside of the bottles are individually washed and cleaned manually thoroughly using detergent and water to remove any kind of dirt, mud or foreign object, and scraped if necessary

Cleaning the interior of the bottles using hot water combined with Sodium carbonate

Once the outside of the bottles are thoroughly washed & cleaned, the inside of the bottles are cleaned starting off with hot water mixed with Sodium carbonate. Sodium carbonate is used as a mild degreasing and cleaning agent.

Cleaning and disinfecting the interior of the jars using Hydrogen peroxide –

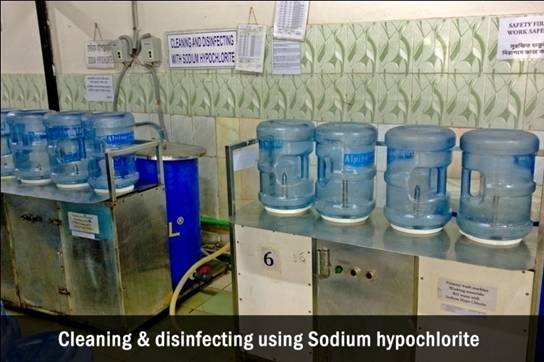

Cleaning and disinfecting the interior of the jars using Sodium Hypochlorite

In the previous steps , Stainless steel fountain type cleaners equipped with four nozzles, solenoid valves, push switches, timers, chemical solution holding tanks, etc. perform the inside cleaning job.

There are two machines (per stage) and each machine has four nozzles. Chemical solution for cleaning is periodically topped up when the level goes down and after sometime, it is drained and replenished with fresh charge.

Standard Operation Procedure (SOP) is clearly written and exhibited near the machines and is strictly followed by the operators.

Lastly the jars are then sent to final stage of washing. In final washing jars' inside and outside area are washed, rinsed with hot product water (57 °C).

Product water means the water that has been processed to make water microbiologically safe and impart required value of TDS, pH etc.